Once a parasite population has become resistant to a parasiticide and it cannot be properly controlled any more, it's usually too late to "save" the product (and most probably its chemical class), but it is not too late to sort out the parasite problem, even if it can be complicated and may require changing some usual management practices in the property.

However, if the parasite population was already resistant to one chemical class and develops resistance to another chemical class (i.e. it becomes multi-resistant) things become more difficult, because the number of chemical classes with different mechanisms of action is limited.

In general, once resistance to a chemical class has developed in a property, with very few exceptions the only realistic solution is to change to products with another mechanism of action, i.e. to change to another chemical class. In addition it is necessary to implement all preventative measures and all non-chemical control options of the parasite that do not require excessive resources.

Increasing the dose or using the product more frequently may solve the problem in the short term, but it worsens it in the long term. In addition it can be unsafe for the animals and the operators and can produce excessive illegal residues in meat, milk or wool that may lead to commercial problems in the export of such products. If for whatever reasons increasing the dose seems unavoidable, it is better to treat the animals twice at the recommended dose than once at the double dose. The risk of tolerance problems is lower and in some cases two consecutive normal treatments are more effective than one treatment at twice the recommended dose.

In fact, Integrated Pest Management (IPM) should be applied instead of relying exclusively on the massive use of parasiticides.

Obviously, all the measures for preventing the development of a second resistance are valid and must be applied for preventing the appearance of any resistance at all.

In the following several measures to prevent resistance development are explained, which are independent of those non-chemical control alternatives that are explained in the specific articles for each parasite, and in the articles on biological control, vaccines and medicinal plants.

Changing the chemical class to prevent or solve a resistance problem

The crucial rule when dealing with resistance to a particular product is: if resistance has already been confirmed or if it is suspected, you should change to a product with a different mechanism of action, which mostly means, to change to another chemical class. Changing the brand, or the formulation, or the delivery form or the active ingredient is not enough. But don't forget that some chemical classes show cross resistance (e.g. organophosphates and carbamates).

The problem is, that from the hundreds of different external parasiticides available in most markets, about 95% contain active ingredients from one of the following chemical classes:

- organophosphates: e.g. coumaphos, diazinon, ethion, dichlorvos

- synthetic pyrethroids: e.g. cypermethrin, deltamethrin, flumethrin, permethrin

- amidines: maily amitraz

- phenylpyrazoles: mainly fipronil

- macrocyclic lactones: e.g. ivermectin, eprinomectin, doramectin, moxidectin, abamectin

In the case of anthelmintics, about 95% of the products contain

- benzimidazoles: e.g. albendazole, fenbendazole, oxfendazole

- imidazothiazoles: maily levamisole

- macrocyclic lactones: e.g. ivermectin, eprinomectin, doramectin, moxidectin, abamectin

- tetrahydropyrimidines (mainly pyrantel) in horse products

This means: hundreds of brands, but only 5 ectoparasiticidal and 4 anthelmintic chemical classes, i.e. 5, respectively 4 different mechanisms of action.

Product rotation to prevent or delay resistance development

Product rotation refers to the periodic alternation between parasiticides belonging to different chemical classes with different mechanisms of action, before resistance to one of the chemical classes has developed (e.g. rotation between an organophosphate and a synthetic pyrethroid). If resistance to one of the chemical classes used has already developed in a property, it makes no sense to continue using it in a rotation program.

There are still different opinions regarding the best long term strategy to follow for delaying resistance development:

- Exhausting a chemical class using it without interruption until it doesn't work anymore, and then change to another chemical class.

- Rotating periodically among chemical classes with different mechanisms of action before any of the products used has shown signs of resistance.

In other words, if you have products of three different chemical classes available for the control of a given parasite, which strategy will need more time for the parasite population to develop resistance to all three chemical classes? Exhausting one chemical class after the other? Or rotating among the three chemical classes?

There is no definite answer to this question applied to specific parasites and to every possible chemical class involved, and confirmed in field trials. Among other reasons because such field trials would be extremely expensive and would take years if not decades to be run.

Until the end of the 1990s, most companies recommended exhausting a chemical class before switching to another one, but in fact, without any supporting experimental evidence, rather due to sluggishness, because it is easier not to change, or because "better the devil you know...". However, it must be said that till the end of the 1990s most multinational companies that controlled the parasiticides market didn't have a product range with many different chemical classes that would allow rotation among their own products. They had e.g. an organophosphate and amitraz, but not a synthetic pyrethroid, or vice versa. Or they may have a benzimidazole but not a macrocyclic lactone, etc. The reason was that most active ingredients were still patent-protected, most multinationals were proud of selling only their specialities, and they considered offering generics as unworthy. As a consequence, recommending rotation would have meant pushing a customer to abandon their own product for a product of their competitors, i.e. losing a customer.

In the meantime, 99% of the active ingredients used in livestock parasiticides have lost patent protection, i.e. they have become generics. And any company, including the few surviving multinationals can offer their customers the whole range of chemical classes needed to ensure product rotation without losing them.

As a consequence, the balance has turned in favor of rotation, i.e. periodically alternating between chemical classes with different mechanisms of action before any of the products used has shown signs of resistance. This is sometimes also called preventive rotation. Among external parasites experimental data are available suggesting that preventive rotation is in fact better in the case of horn flies and cattle ticks. And preventive rotation is officially recommended in many countries in other related fields, e.g. in the use of antibiotics in humans and livestock, as well as in the control of many agricultural pests. There are no solid arguments to support that this would not apply to livestock parasites (ticks, flies, gastrointestinal worms, etc.). Anyway, if someone changes to another product before the one he is using becomes "exhausted" due to resistance, he does not take an undue risk: at worse, if he does not like the new product, he can still return to the abandoned one. And the few treatments with the product he doesn't like may have reduced the number of perhaps already resistant individual parasites in his property.

When is it recommended to rotate?

Depends on the reproductive speed of each parasite in a given environment, which usually is related to the specific biology of each parasite, to ecological and climatic conditions, and to the availability of hosts for feeding and reproducing. The faster a parasite can reproduce, the more frequently you should rotate.

Under laboratory conditions, some fly species (e.g. houseflies, horn flies) exposed to a parasiticide may develop some level of resistance after only 10 generations, and after 20 to 30 generations resistance may reach very high levels. Comparable results have been reported for development or resistance of Haemonchus roundworms to anthelmintics.

In the field, cases have been reported where resistance to a new parasiticide developed in only 3-4 years after starting using it, e.g. horn flies to synthetic pyrethroids. However, the time it will take in the field is often unpredictable and may be quite different in the various countries and regions. In some cases it took >35 years (e.g. resistance of Lucilia cuprina to cyromazine in sheep in Australia), whereas in other cases it took <3 years (e.g. resistance of some gastrointestinal roundworms to monepantel in sheep in New Zealand). In addition, it seems likely that once a parasite population has developed resistance to one chemical class, development of resistance to a second and subsequent chemical classes will be faster.

Based on this, considering the number of generations that a parasite can go through in a particular environment, and aiming at not exceeding 15-20 generations being uninterruptedly exposed to the same chemical class, the following recommendation will keep you on the safe side in order to prevent or at least delay resistance development:

- cattle ticks (Rhipiceiphalus=Boophilus microplus): 3-5 generations a year: rotate every 3 to 5 years

- horn and buffalo flies (Haematobia irritans): 10+ generations a year: rotate every 12 to 18 months

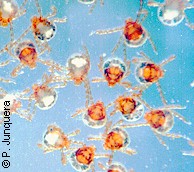

- red fowl mites (Dermanyssus gallinae): 15+ generations a year in confined operations: rotate every 6 to 12 months

- houseflies (Musca domestica): 10+ generations a year: rotate every 12 to 18 months

- blowfly strike (Lucilia cuprina): 4-8 generations a year: rotate every 3-4 years

- gastrointestinal roundworms: 4-10 generations a year: rotate every 2-3 years

- liver flukes (Fasciola hepatica): 1-3 generations a year: rotate every 4-6 years

- sheep lice (Damalinia=Bovicola ovis): up to 10 generations a year rotate every 1-2 years

If changing the product doesn't cause a management problem, it can be rotated earlier. Follow specific official recommendations for your country or region if available.

Be aware that no single really new (i.e. with a new mechanism of action) ectoparasiticide for livestock has been introduced in the market in the last 30 years. And the last really new anthelmintics for livestock were introduced in the 2000s (monepantel and derquantel), more than 30 years after the penultimate (ivermectin).

Although numberless companies are constantly introducing "new products", what is often really new is the logo, the packaging, the formulation, the mixture, the delivery form, the dose, etc., but not the mechanism of action. The reason is that most surviving large animal health companies have lost interest in finding new active ingredients for livestock because it is too expensive, it takes too long to develop, and often it does not pay back. And the small companies just can't do it and rely on generics, i.e. old active ingredients. This means also that you cannot count on really new active ingredients becoming available soon to solve a future resistance problem.

Mosaic treatments to delay resistance development

Mosaic treatments consist in treating simultaneously part of the animals in a property with one parasiticide, and the rest of the animals in the property with another parasiticide of a different chemical class with a different mode of action. This makes only sense if the parasites can be considered as belonging to the same golbal parasite population of the property, and if the parasite population is susceptible (i.e. not yet resistant) to both chemical classes. The rationale behind this strategy is that you would be attacking the parasite population simultaneously with two different mechanisms of action, which is broadly considered as preventing or delaying resistance development.

An example for controlling horn flies in cattle could be treating half the animals in the farm with a diazinon ear-tag, and the other half with an ivermectin pour-on. Another example for controlling blowflies in sheep could be to treat half the animals with a dicyclanil spray-on, and the other half with spinosad jetting.

Against houseflies there are numberless options for mosaic treatment, e.g. combining the use on an adulticide (baits, traps, fumigation, paints, etc., mostly with organophosphates, carbamates, neonicotinoids) with a development inhibitor or a larvicide (e.g. diflubenzuron, cyromazine, methoprene, etc.) for manure treatment.

There are no major difficulties in applying mosaic treatments against gastrointestinal roundworms.

Mixtures of antiparasitic active ingredients

The use of mixtures of active ingredients has been broadly discussed. In the context of resistance prevention the key rule is that it only makes sense if:

- The active ingredients in the mixture have a different mechanism of action,

- The concerned parasite is susceptible to all the active ingredients in the mixture, i.e. it has not yet developed resistance to any of them.

If this applies, it is generally assumed that simultaneously attacking the parasite with two (or more) different mechanisms of action will significantly delay or even prevent the development of resistance to the active ingredients in the mixture. Concerning resistance prevention, mixtures are normally worthless if the actives have the same mechanism of action.

If the parasite being addressed is already resistant to one of the active ingredients in the mixture, using the mixture will aggravate it, and the risk of development of multi-resistance is higher than using the active ingredient without resistance alone.

From the point of view of resistance prevention and for external parasites, there are not that many possible mixtures that make sense. Most such mixtures (for dipping or spraying) contain e.g. :

However, resistance of horn and buffalo flies as well as cattle ticks to synthetic pyrethroids is widespread. Commercially it can make sense to use a mixture containing a synthetic pyrethroid and something else: if one does not work, the other one may do the job. But the risk of worsening the resistance problem is real.

The same applies to the control of gastrointestinal roundworms (and also liver flukes). There are numberless mixtures among sheep and cattle wormers combining 2, 3 and even 4 of the following major anthelmintic chemical classes:

- levamisole

- benzimidazoles (e.g. albendazole, fenbendazole, oxfendazole, etc.)

- macrocyclic lactones (e.g. abamectin, ivermectin, moxidectin, etc.)

- closantel

- tetrahydropyrimidines (mainly pyrantel) in horse products

As already mentioned for ectoparasites, if someone does not know whether gastrointestinal roundworms in his property have already developed resistance to one of those chemical classes, using a mixture may be convenient: "at least one may do the job". But from the resistance prevention point of view, such mixtures are quite likely to accelerate the development of multiple resistance.

Using mixtures makes also sense when each active ingredient is targeting different parasites that infect livestock simultaneously, e.g. combining a nematicidal wormer (e.g. a macrocyclic lactone or levamisole) against gastrointestinal roundworms with a flukicide against liver flukes (e.g. triclabendazole, closantel or clorsulon). Nematicidal wormers do not control liver flukes, and most flukicides do not control roundworms. However such mixtures do not attack parasites with two different mechanisms of action, but each parasite with one mechanism of action, i.e. they are not contributing to delay resistance.

Parasite refuges

Parasite refuges are groups of hosts or locations where part of the parasite population in a property or a region is not exposed to parasiticides and consequently is not submitted to selection pressure for becoming resistant to the drugs.

Refuges favor the survival of susceptible parasites (i.e. non-resistant) that can mix with the more-or less resistant ones and contribute to dilute or diminish resistance of the global parasite population.

Depending on the parasite, refuges can be a group of livestock that remains untreated on purpose, where parasites can developed without selection pressure; wildlife that are also hosts to the same parasites as livestock (e.g. deer in cattle properties) but are not treated; or specific habitats that remain untreated where parasites spend some time and thus are not submitted to selection pressure

In the context of resistance prevention it is always a good idea to maintain or allow such refuges. However, it is not always easy to achieve: e.g. there may be not enough wildlife in a property or it may be undesirable for whatever reason.

A major difficulty is that there is almost no seriously investigated practical experience concerning how much untreated livestock (or wildlife) and for how long can ensure that the susceptible parasites developing in such refuges are enough to impact the global resistance level of the parasite population in the property. Running such trials would take years if not decades and cost huge amounts of money, and what is valid for one parasite, or one host, or one active ingredient, or one region may not be applicable to others. A few studies on livestock have been published during the last years, and some useful information is also available from crop protection. But it is too early to make any practical recommendations for most countries.

Reintroducing susceptible parasites in a property

It cannot be excluded that in a particular property a parasite population becomes simultaneously resistant (i.e. multi-resistant) to all chemical classes available for its control.

And the risk is particularly real for cattle ticks, gastrointestinal roundworms, houseflies, blowflies, and red fowl mites. A field strain of cattle ticks was reported in Brazil in 2014 that was resistant to organophosphates, amitraz, fluazuron, fipronil, ivermectin and synthetic pyrethroids.

The risk is increasing also because investments in the discovery of really new active ingredients (i.e. with a new mechanism of action) for controlling livestock parasites has strongly diminished in the last decades. The last ectoparasiticide with a really new mechanism of action against ticks or adult flies in livestock was introduced almost 40 years ago (ivermectin).

What to do in such a case? Une option discussed among some specialists and theoretically reasonable is to re-introduce susceptible parasites (i.e. non-resistant) in such a property in order to let them mix with the local resistant population and thus dilute its level of resistance. But there are numerous hurdles for the practical success of such a theoretical proposal.

First hurdle: after re-introducing susceptible parasites parasiticidal treatments had to be stopped for an uncertain period of time (months) years?) since otherwise the newly introduced susceptible parasites would be the first to be killed. This would mean switching to non-chemical control methods that would not selectively kill the susceptible parasites. But such non-chemical methods may not be available, or may not be effective enough against the concerned parasite.

Second hurdle is that the re-introduced susceptible parasites have to be biologically more vital than the resistant ones, i.e. they have to have some biological advantage that makes their genotypes prevail over the resistant ones after a few generations of interbreeding. However, such susceptible parasite strains can often be found only in research labs, and such strains are mostly less vital, i.e. less trong than wild strains. The reason is that they have been kept for decades under laboratory conditions excluded from natural selection and thus have accumulated "weaknesses" and malformations that make it unlikely for them to prevail over their wild fellows.

One more hurdle is that nobody knows how many such susceptible individuals should be released in a property in order to invert or at least reduce the level of resistance of the local population. The only to some extent comparable experience that has been accomplished in the field is the release of sterile males of the screwworm fly (Cochliomyia hominivorax), first in the US and afterwards in Mexico and Central America. To make this possible, facilities for fly production at an industrial scale had to be developed and run in order to release hundreds of millions of flies during decades, investing hundreds of millions of dollars. Even if the aim would be to solve a problem in a particular property or region and not in a continent, it would be required to produce considerable amounts of cattle ticks, or horn flies, or gastrointestinal roundworms, which are neither easy nor cheap to produce.

In 2021, investigations studying the introduction of susceptible H. contortus worms in a farm with strong resistance to benzimidazoles, macrocycic lactones and levamisole, showed that after about 3 years (without treatments!) the worm population became susceptible to those anthelmintics. However, when anthelmintic treatments were resumed, resistance reappeared already within about 1.5 years. The authors suggested that the susceptible worms introduced lacked environmental fitness when compared with the resistant worms

And finally, even if you can overcome these hurdles for a given resistant parasite species, it is only valid for that species. Say, if you have solved a problem with a barber's pole worm (Haemonchus contortus) infection, you may have not solved a concomitant problem with the black scour worm (Trichostrongylus colubriformis), which are two gastrointestinal roundworms that are often found together in sheep properties and that also tend to develop resistance to the same nematicides.

Links to other articles on resistance in this site: